ATTENDING TO THE FINEST DETAILS INCLUDING SIZE, SHAPE, MATERIALS, AND EASE OF USE

SEIRIN uses a fully automated state-of-the-art manufacturing process for developing the finest,smoothest and safest acupuncture needles in the world. The package design of Pyonex givescareful attention to hygiene and exceeds all acupuncture needle manufacturing standards.

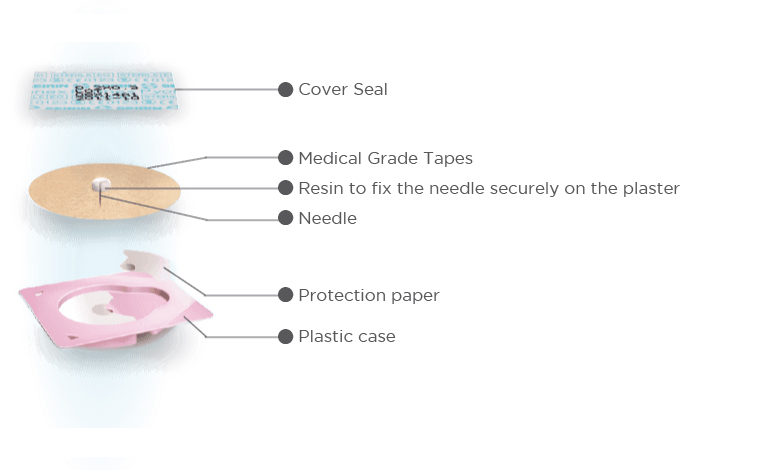

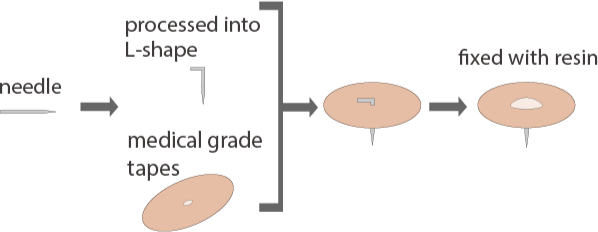

Needle Fabrication

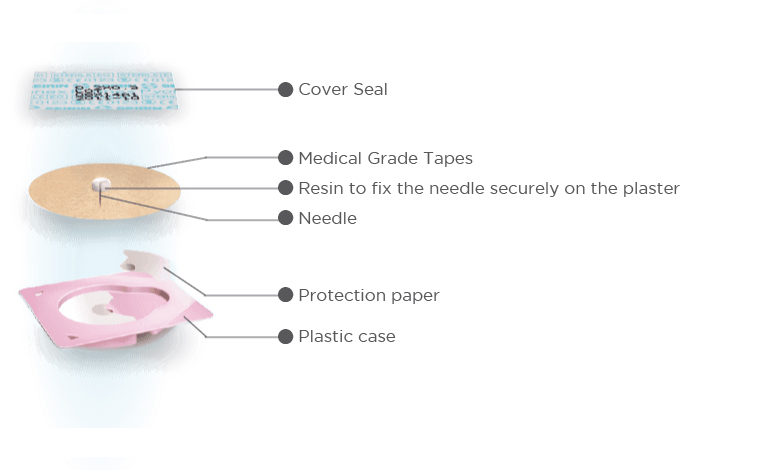

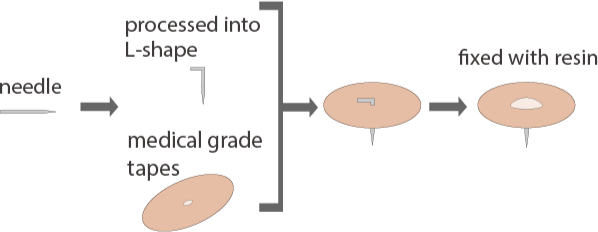

The unique manufacturing process of the PYONEX ensures that each needle is securely bonded to the Micropore TM plaster so the needle will never separate.

Protective Layer

Divided into two sheets, the protective layer allows practitioners to hold the product firmly without making contact with the needle or adhesive tape.

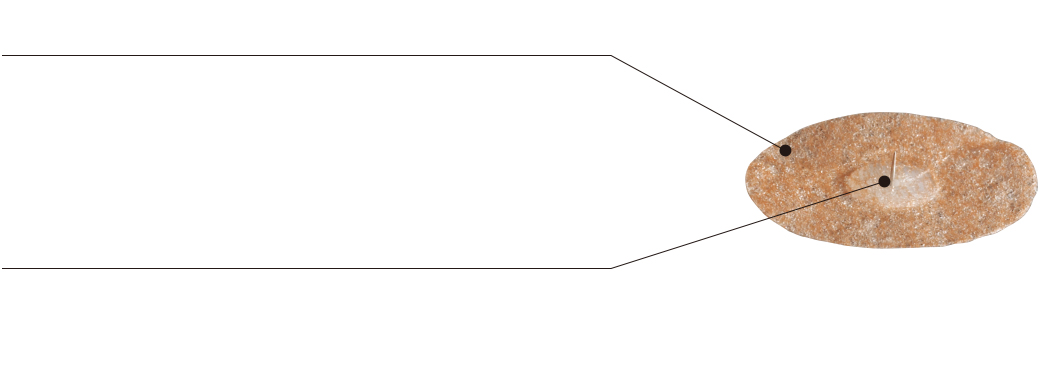

Medical Grade Tapes

The latex-free Medical Grade Tapes is breathable, water-proof and adheres to the skin for long-term placement.

Needle

Composed of Japanese Surgical Grade stainless steel and manufactured in Japan.

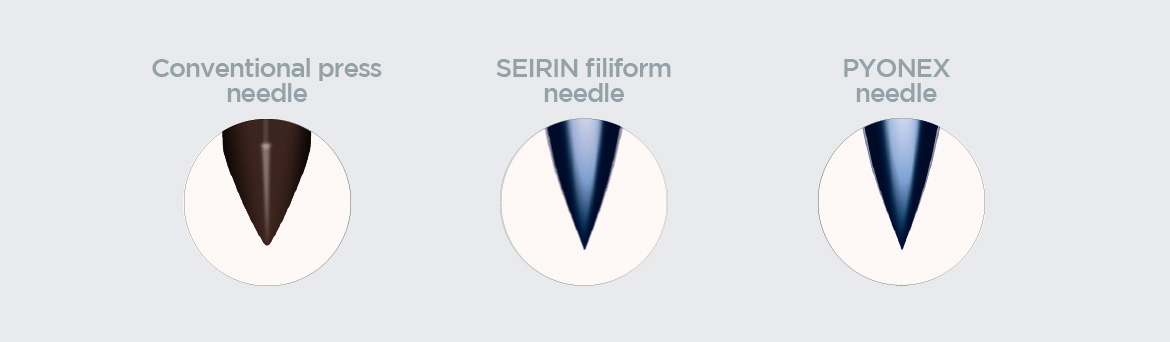

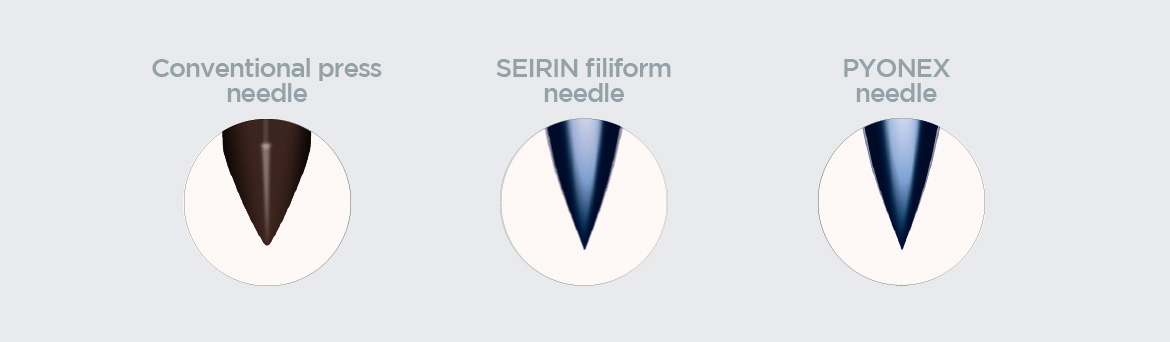

PYONEX NEEDLE TIPS PROVIDE THE SAME EFFECT AS ACUPUNCTURE NEEDLES

Unlike the conventional press needle, PYONEX, featuring the same sharpness as the SEIRIN filiform needle, can provide treatment effects comparable to regular acupuncture, if applied properly to sufficient depth.

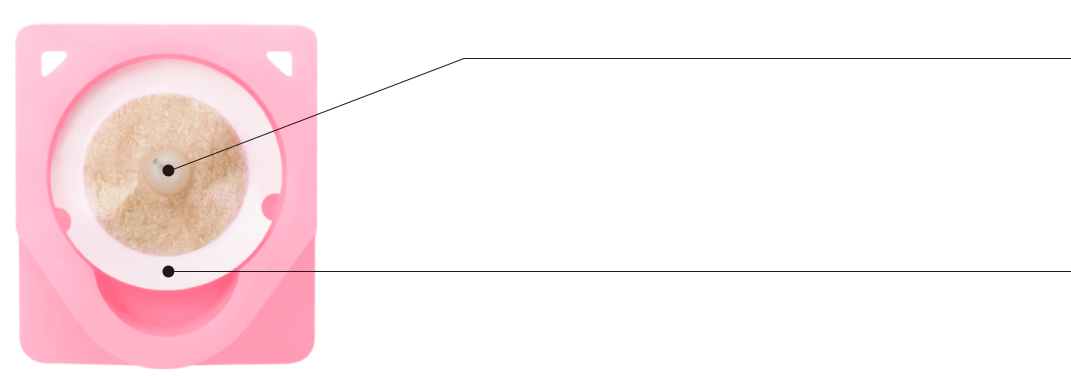

STRUCTURE OF PYONEX

“Virtually pain free” intradermal needles with an innovative L-Shaped, round-head design. This unique design feature ensures a strong bond be¬tween needle, resin and medical-grade tape.

STERILITY AND SAFETY

The blister packaging of Pyonex is quite revolutionary, combining multiple disciplines like cartridge-type injection molding, sheet packaging, Resin, and polymer plastics that maintain sterility throughout the packaging process.